Working principle of permanent magnetic lifter

The permanent magnet lifter is designed by according to the continuity principle of the magnetic flux and principle of the magnetic field. The magnetic circuit is designed into a plurality of magnetic systems, and the relative magnetic field is added to achieve the addition or cancellation of the magnetic field, thereby achieving the purpose of holding and unloading of the lifting object.

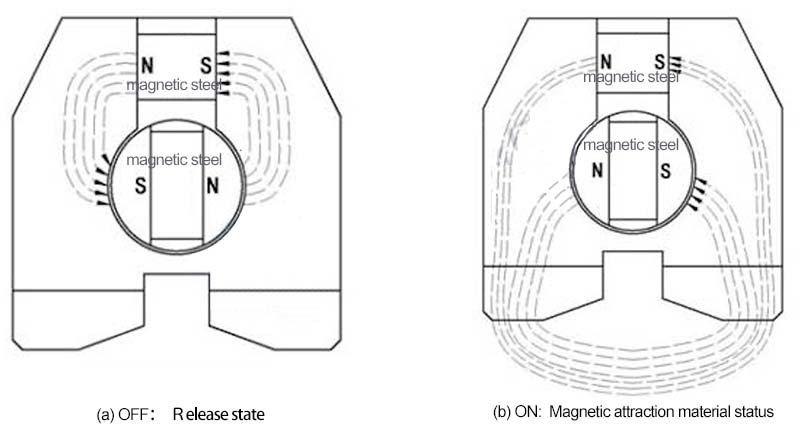

The working principle is as shown in the picture.

When the magnetic pole is in the state of (a), the magnetic flux start from the N pole, passes through the yoke, passes through the ferromagnetic workpiece, and then returns to the yoke to enter the S pole of the magnet. In this way, the workpiece can be firmly attracted to the working surface. When the magnetic pole is in the state of the figure (b), the magnetic force line is less than the working pole surface, and the closed circuit of the magnetic circuit is formed inside the permanent magnet lifter, no magnetic line comes out from the working pole surface, so the workpiece can be unloaded without generating suction.

Permanent magnet lifters are widely used in the machinery manufacturing, they are easy to operation, energy saving and environmental protection. It is small in size, light in weight and high safety factor. The maximum loading force is 2.8-4 times of the working load. They are used for connection with the hoisted workpiece during lifting (for example: with electric chain hoist, wire rope electric hoist, etc.) for moving iron plates, blocks and cylindrical magnetic materials.